Natural Cork Floating

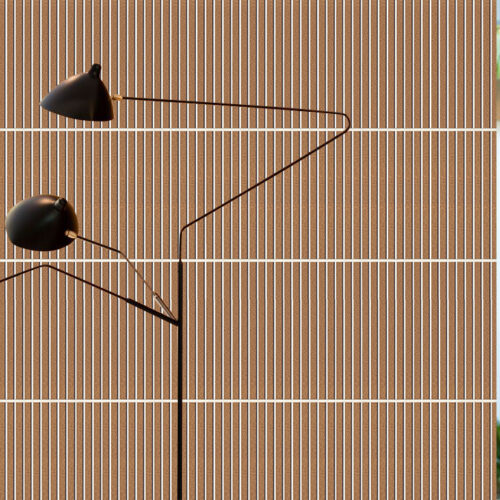

3D Acoustic Wall Panels

Natural Cork Floating

Natural Cork Floating

3D Acoustic Wall Panels

Natural Cork Floating

3D Acoustic Wall Panels

3D Acoustic Wall Panels

Wave Wood – 25/32″ (20mm) – 3D Acoustic Cork Wall Panels (WWWo20)

3D Acoustic Wall Panels

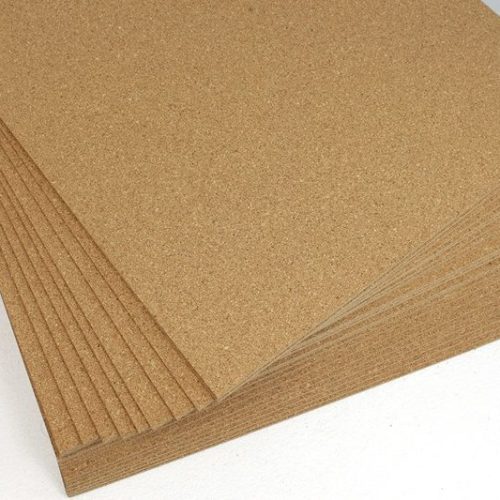

Swiss Design Cork

American Red Oak – 7/16″ (11mm) – Swiss Design Cork Floating (FRed11)

3D Acoustic Wall Panels

Slatwall Perla – 43/64″ (17mm) – 3D Acoustic Cork Wall Panels (WSwP17)

3D Acoustic Wall Panels

Slatwall Dark Natural – 43/64″ (17mm) – 3D Acoustic Cork Wall Panels (WSwDN17)

Learn more about our Flooring products in our Buyers Guide and Deep Dive For Flooring (click here).

Forna Product Overview

Why do you want to choose Cancork?

At Cancork, we firmly believe that cork flooring is superior to any other type of flooring for indoor applications. Our wide selection of cork flooring options cater to every design preference and are sourced from sustainable production in Portugal. We have partnered with top installers, retailers, and professionals across Canada to ensure the best installation for your home. Cork flooring offers properties such as surface waterproofing, making it a fantastic alternative to vinyl tiles, vinyl sheets, rigid core flooring and hardwood floors. We have been known as the most-trusted cork flooring store in Canada for many years.

We offer a range of traditional and digitally generated designs, including top layers of different woods and real wood overlays for an authentic finish. Our cork and cork-based floors are sourced from prime locations and factories in Europe. Furthermore, we offer unique wall and ceiling tiles that will give your home a luxurious look and feel. We are unique in Canada and ship all across the country.

Our customers love our floors for their superior feel and look compared to alternatives such as linoleum and vinyl flooring. We take great care in selecting the best materials for our products to ensure customer satisfaction. As a family-run business, we ask our customers to leave reviews and encourage you to browse our reviews on Google and Facebook to get a better understanding of our products and service. We ship nationwide and you can receive a quote by entering your location during checkout.

Greenguard Gold

Improve indoor air quality

Ultra Low VOC

Safe and Clean Indoor Air

U.S. Green Building Council

LEED points for green building

Das Kork Logo

Exceed Highest German Standards

Customers’ Reviews

At our company, our mission is to help you turn your dream home into a reality at an affordable price. Not only that, but our customers also rave about the ease of installation and luxury design and quality of our floors. We understand the importance of a company that prioritizes your needs and that is why we go above and beyond to ensure 100% satisfaction in all of our work. We have a wide selection of cork flooring options that are perfect for high-traffic areas like kitchens and bathrooms. Our customers trust us and here is what they have to say about our products and services:

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating

Natural Cork Floating